Exposed hoppers with discharge by grab and the environmental issues to be considered.

Due to their polluting potential, hoppers with unloading by grabs, exposed to the wind, can be highly harmful to the environment.

In this article, we will deal with the critical features of this class of equipment with regard to its environmental liability.

The main problem to be considered is the typical configuration of this type of device, in which the receiving grid is in the same plane as the top of the hopper, and the product is unloaded through the grab just above this grid.

This configuration, combined with the speed of the winds, allows the dust generated by unloading the product to be spread to the environment, which can be easily seen by the cloud of particles that forms.

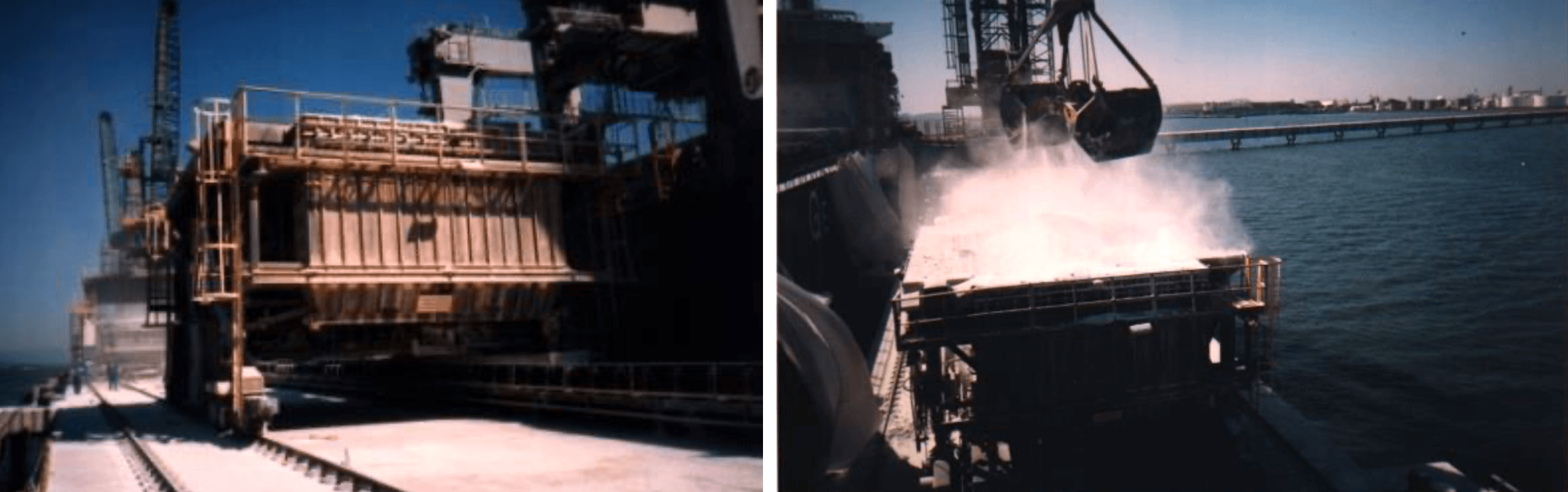

The photo on the left shows a hopper with a powerful suction system without the side plates. The photo on the right shows the material being unloaded, while the wind drags the powder produced by the process out of the hopper.

The photo on the left shows a hopper with a powerful suction system without the side plates. The photo on the right shows the material being unloaded, while the wind drags the powder produced by the process out of the hopper.

Experience shows that the enclosure of the grab unloading area is the best alternative for reducing the environmental impact of hopper operation processes.

This result is achieved by vertically closing the four sides of the hopper at its top.

However, this technique leads to two new considerations.

The first is where to place the filters, fans and the rest of the cleaning system. One possible solution is to use the cleaning filters themselves to close the sides of the hopper, together with the fans and other system components. In this case, the hopper needs to receive heavy reinforcements to support the weight of the entire set, which can make it difficult to move the equipment.

The second limitation is regarding the operating aspect of the system.

Enclosure increases ship unloading time: the operator needs to direct the grab to the bottom of the hopper, unload the product and wait between 1 and 5 seconds before slowly lifting the assembly out of the enclosed area, allowing the suction system operates.

Considering that the operator needs to perform the unloading in the shortest time possible, but that, on the other hand, the degree of efficiency of the suction depends on its observance of the interval required for the suction process, we are faced with a dilemma that needs to be equalized case-by-case.

The problem is enhanced when there is the presence of materials that produce a lot of dust, that have hygroscopic features, or even in an open environment with high relative humidity.

Therefore, there is no guarantee of efficiency of the suction process in ship unloading operations when the wind has speeds above 10 meters per second. When this occurs, the drag force of the wind overcomes the suction force of the system, causing the release of dust into the environment.

Grabs unload a multitude of products such as soy, bran and corn. In these cases, the materials used to build the suction equipment are the same as those used in conventional systems. However, when it comes to aspire corrosive products, a specific study of the application is recommended, as certain precautions must be taken during construction.

It is also recommended that when working with highly aggressive materials such as sulfur, the suction is turned off in order not to compromise the equipment's durability.

It is also recommended to turn off the suction system in cases where the products do not present dust emanation. In this way, the operator will be able to speed up the unloading operation.

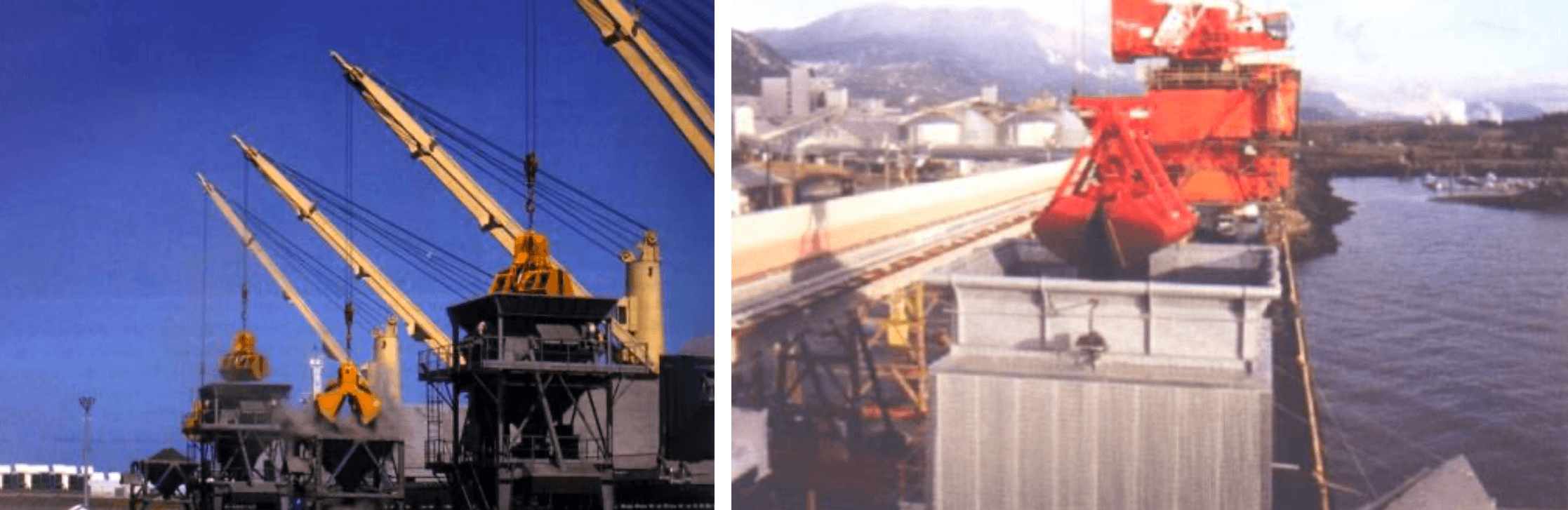

In the photo on the left you can see several types of hoppers equipped with side plates or without closure. The photo on the right shows an ideal project with recommended side closure.

In the photo on the left you can see several types of hoppers equipped with side plates or without closure. The photo on the right shows an ideal project with recommended side closure.

Finally: companies that work in discharges with grabs are often unaware of the specialists' recommendations and end up purchasing suction systems without side plates or even with insufficient height. Given this reality, the supplier of suction systems in hoppers must take care to always guide the customer with reference to the operation and functioning of the system.