TMSA Compact Filter (BIN-VENT)

The main feature of Compact Filters used in solid bulk handling systems is the fact that they aspirate the particulate material directly onto the source that generates dust.

With this, the unloading of the collected material is carried out at the same point as the collection, which eliminates the need for fans and the inconvenient piping connected between the dust collection points and the central filtering systems.

Another striking feature, its compact shape, is achieved thanks to the use of high-performance pleated cartridges, with a large filtering area in a small space, thus replacing several conventional bags.

Compact Filters can be installed at the most diverse points of dust emanation, such as: belt transfers, silos, discharge and intake chutes, elevator feet or heads and other points where processes that generate dust occur.

Compact filter installed in a horizontal position when unloading a conveyor belt.

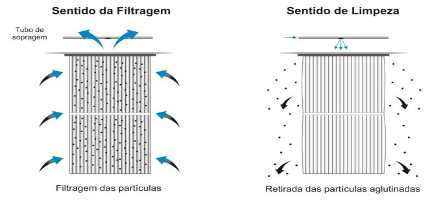

The working principle of a Compact Filter is the separation of solid particles from the gaseous medium. During this action, the air containing the pollutant is sucked through the bottom of the filter and passes through the surface of the filter cartridges from the outside to the inside. In this way, the suspended solids are retained on the outside of the cartridges and the clean gases go to the plenum, where they are admitted by a centrifugal fan and the air, free of impurities, is returned to the environment.

The filter media cleaning system is performed by means of pulsating jets that are controlled by an electronic programmer. It allows the pulse frequency and duration of the bag cleaning cycle to be regulated.

The programmer is mounted on a printed circuit in fiberglass encapsulated with epoxy resin. Its actuation periods can be set to pulse intervals between 1 and 60 seconds with the duration of each pulse set between 0 and 1 second.

The cleaning process works through a series of valves that periodically release high-energy compressed air through the blowing tubes inside the cartridges, resulting in a shock wave capable of ejecting dust from the external surface of the filtering element. The powder, now in the form of agglomerated flakes, returns by gravity to the reservoir fixed to the filter body.

Compact Filters are designed to separate solid particles above 1 micron, achieving efficiency up to 99.6%. This level of effectiveness meets the standards of the ABNT - Brazilian Association of Technical Standards, AMCA - Air Movement and Control Association and ASHRAE - American Society of Heating, Refrigerating and Air Conditioning Engineers Industrial Ventilation, as well as the NR12 standard for safety at work on machines and equipment.

The design of a Compact Filter is determined taking into account the product to be aspirated, the required flow rate in relation to size, the amount of dust at the collection point and the required filtering area.

From these variables, Compact Filters present a series of arrangements and models that satisfy the most varied applications, resulting in different sizes, suction flows or installation positions, whether vertical or horizontal.

Compact filters basically consist of three parts:

- Fan and motor set;

- Cartridge cleaning system compartment - where the solenoid valves and the internal compressed air blowing tubes are located;

- Compartment where the blow venturis and pleated filter cartridges are installed.

Pleated filter cartridges are without doubt the most important part of the filtering system. Therefore, the correct choice of fabric is crucial for the good performance and separation efficiency of a Compact Filter.

Compact Filters require little maintenance, but certain precautions must be taken mainly with regard to the operating conditions of the filter cartridges. For example: specific conditions must be taken into account when filters are installed in exposed locations or where they may be affected by humidity, especially if the operating regime is discontinuous. In these cases, moisture can be absorbed by the fibers or remain inside the textile material, causing loss of permeability.

Additionally, if the solid particles present are hygroscopic they will also absorb moisture, becoming sticky and agglomerating in the cartridges, which causes an increase in pressure drop.

Clean, unused fabric.

Clean, unused fabric.

Beginning of the pre-layer on the filter fabric.

Beginning of the pre-layer on the filter fabric.

Another factor to be taken into account is whether the particles are capable of holding electrical charges with a signal opposite to that of the textile material. If this phenomenon tends to occur, then special cartridges are employed in order to allow the necessary grounding.

Many operators are concerned about the layer of dust present on the filter fabric. This layer is nothing more than the pre-layer. It forms on the surface of the filtering element and also acts as a filtering element, improving retention properties.

However, if over time this layer increases too much, the pores of the filtering elements close, with a consequent increase in pressure drop.

Clean, unused fabric.

Beginning of the pre-layer on the filter fabric.

ADVANTAGES OF A COMPACT FILTER

- The set is mounted directly on the source of dust, aspiring and discharging at the same point;

- The dimension of the filtering set is reduced, incorporating in a single piece all the elements necessary for the operation;

- Filter cartridges can be removed, washed and returned to use without changing their physical-chemical properties;

- Compact filters can be installed at the most diverse points of dust emanation;

- Low maintenance and great durability;

- Motors and other parts are explosion proof;

- Radial fan is self-cleaning and explosion proof;

- The probability of imbalance is practically nil, as this system prevents adherence of foreign bodies;

- The entire set receives special paint against corrosion;

- Compact filters do not need discharge seals for the discharge of the aspirated material, preserving the environment and improving the work environment;

- System operation is facilitated by the drastic reduction in the workmanship involved in cleaning adjacent areas;

- Can be adapted to existing equipment;

- As it is a compact equipment, the cost of structures and foundations is reduced or non-existent;

- It can be used in processes that involve the most diverse products and, in some cases, it is enough to exchange or wash the filter cartridges;

- The electronic programmer is intelligent and can also be regulated in order to save compressed air;

- The set has its own independent cleaning system, equipped with a reservoir fixed to the filter body, simply being connected to a compressed air point with a pressure of 7 kg/cm2 at the required flow rate.