What level of efficiency does TMSA guarantee in suction systems?

The efficiency of an suction system is evaluated by two distinct aspects.

The first aspect is the correct air flow in the dust collection process, from the point of particulate emission to the separator. This calculation needs to be exact, allowing the process to be as efficient as possible.

The second factor to be analyzed is the efficiency of separator collection. That is, the amount of residual dust that the collector cannot separate and that ends up being released into the environment.

Therefore, there is a big difference between suction efficiency and pollutant separation efficiency.

When it comes to suction efficiency, a higher suction flow at the particulate emission point is often seen by users as being ideal. However, that is not what happens. Oversizing components results in wasted energy, increased equipment costs, size of filters, motors, piping and other accessories.

On the other hand, if the suction flow is lower than necessary, the fugitive dust will not be fully aspirated at the emitting source, dispersing in the environment, which does not satisfy the parameters established by regulatory agencies.

Thus, both excess and lack of suction represent losses to the process, whether from the point of view of investment or system efficiency.

In the powder separation stage, there are several types of separators: wet, dry or electrostatic.

The most used are of the dry type, such as cyclonic centrifugal collectors, bag filters or pleated cartridge filters. Cyclonic separators, as they have a low separation efficiency - around 85% - are generally used as pre-separators. Bag filters or pleated cartridge filters have a separation efficiency of up to 99.5%, being the most used in dust separation facilities.

A bag filter is made up of several components. However, the efficiency of collection of pollutants is directly related to the quality of the bags or cartridges and their cleaning system.

Therefore, it is essential that these equipment’s are well selected, ensuring that there are no faults in specifications such as grammage, fabric permeability or even factors such as the speed of air passage through the filtering element. In this regard, the system must deliver a good air-to-fabric ratio, optimizing the distribution of particulates between the bags, filter chambers and pre-layer. Other important qualities concern features such as fabric quality and surface finish, factors that prevent premature clogging of the bags, promote pressure loss control, ensure the efficiency of the cleaning system, offer density stability and cleaning system regulation , among others. And not forgetting, the care with the maintenance of the entire system.

Therefore, if all these factors are satisfied, the efficiency of an suction system can be evaluated.

The most common measurement is carried out in the system discharge chimney. Values are expressed in milligrams/m3 (mg/m3), raised by dividing the mass by the volume of passing air.

In Brazil, the norm adopts the primary standards established in CONAMA resolution number 3 of 06/28\1990, which stipulates that no polluting process may emit into the atmosphere an amount greater than 70 mg/Nm3.

Each region can establish its own air quality standard, but when the State does not define it, the national maximum value is adopted. However, there are two different values for measuring particulate emissions. One is the measurement performed right at the exit of the suction equipment, which is expressed in mg (milligrams) and is represented by the ratio of 1/1000 of a gram. The other is measured in µg (micrograms) representing the ratio of 1/10000 gram. In this regard, if we consider particles suspended in air, the values differ greatly in absolute numbers.

The emission measurement guaranteed by TMSA is that performed directly at the output of the suction systems. It is commonly measured in the chimney, just after the bag filters, where values are expressed in milligrams per cubic meter (mg/Nm3). This corresponds to the thousandth part of the gram. For this case, the air quality legislation governed by CONAMA establishes the value previously informed, which is 70 mg/Nm3. The separation efficiency can be measured by a various instruments. However, the most used and reliable are the absolute pumps.

The measurement is carried out at the filter outlet where the pump containing a completely dry special role is placed. After the time necessary to carry out the sampling, the substrate is sent to the laboratory where it is dried and weighed. The difference between the initial and final weight will indicate how many milligrams of pollutant was retained on the paper in a certain time interval/volume of gases. The value will always be given in mg/m3.

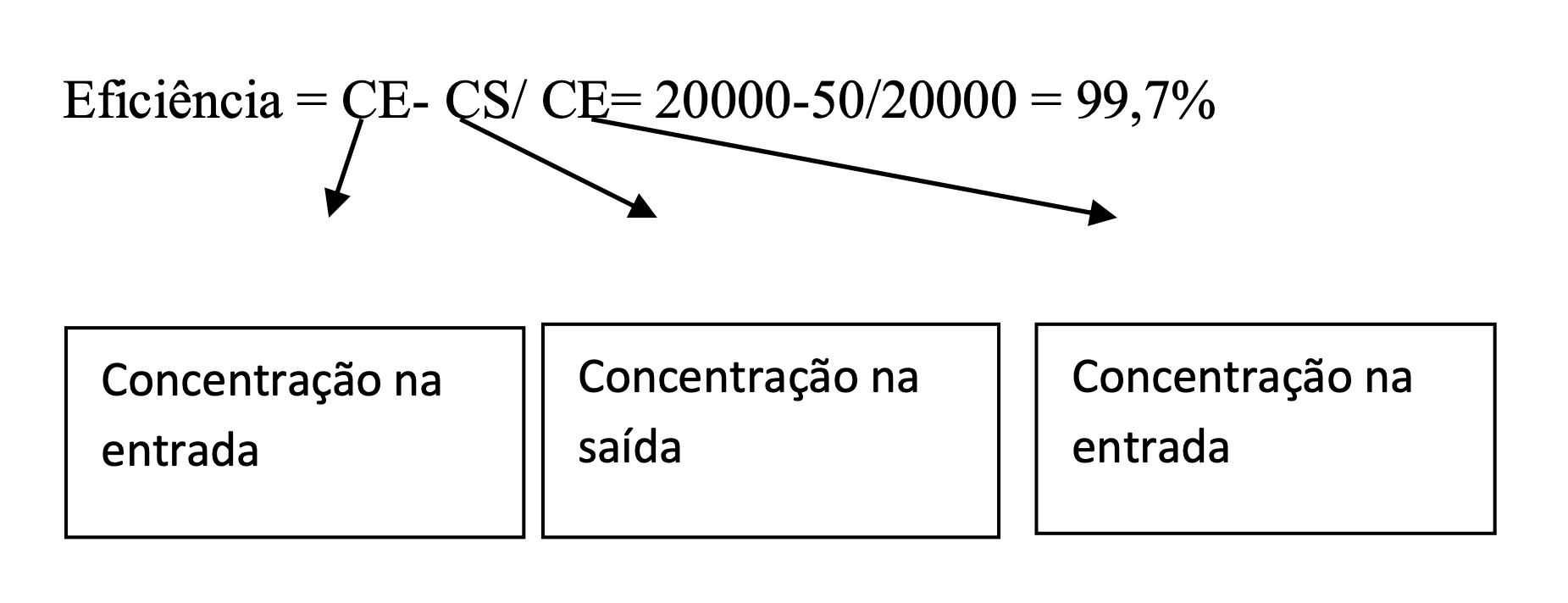

From this measurement, we can know the efficiency of the system. For example, if a filter has a dust load of 20 g/m3 at the inlet and 50 mg/m3 at the outlet, we can use the formula below to determine the efficiency of the filter.

Therefore, TMSA guarantees a maximum emission of 70 mg/Nm3 at the exit of the suction systems, as per the air quality standard established by the national regulatory authority, provided that the concentration of pollutants existing before the installation of the system in the locations is informed and known to be treated.

The pattern informed above may be reduced depending on what the local supervisory body requires. In this case, the project must be revised, and the equipment may change both in size and in values.

TMSA guarantees the maximum emission value informed above, provided that the numbers obtained at all times of monitoring, before and after the assembly of control equipment and particulate abatement, are obtained under the same climatic and operational conditions. In other words, at the same production levels and with the yard wet so that there is no separation of other particulates. Also considered are critical factors, winds above the limit that cause the release of dust accommodated on the ground, galleries or others.

TMSA does not guarantee outdoor ambient air quality in patios, galleries, tunnels, confined areas and outdoor areas in which pollution is expressed in μg (micrograms). In these areas, air quality depends on external factors represented by the sum of all dust emitting sources. As examples, we can mention the winds that drag dust from other places, other industries, trucks circulating in the yard and other factors beyond the control of the suction system in question.

TMSA does not perform particulate emission efficiency analysis. This must be carried out by companies certified by environmental agencies. Such organizations must comply with current regulations, employing updated methodologies and measured instruments, in addition to offering measurement reports.