Job Report Motasa

PROJECT SCOPE:

MOTASA It is a company with 65 years, based on the continuous innovation of its products and services, responsible for the production of meals and pre-mixes for the bakery market. Seeking to modernize of its operations, the company established a partnership with TMSA to implement new technologies from Industry 4.0 in its unit. The company identified that the constant monitoring of PCM (Pre-Cleaning Machine) equipment would help to predict eventual failures and, thus, acting in a predictive manner, increasing the availability and productivity of its processing unit, since its machines they are fundamental in the production chain and cannot stop. In this way, studies were started on the use of the TMSA 4.0 Platform - Digital Revolution .

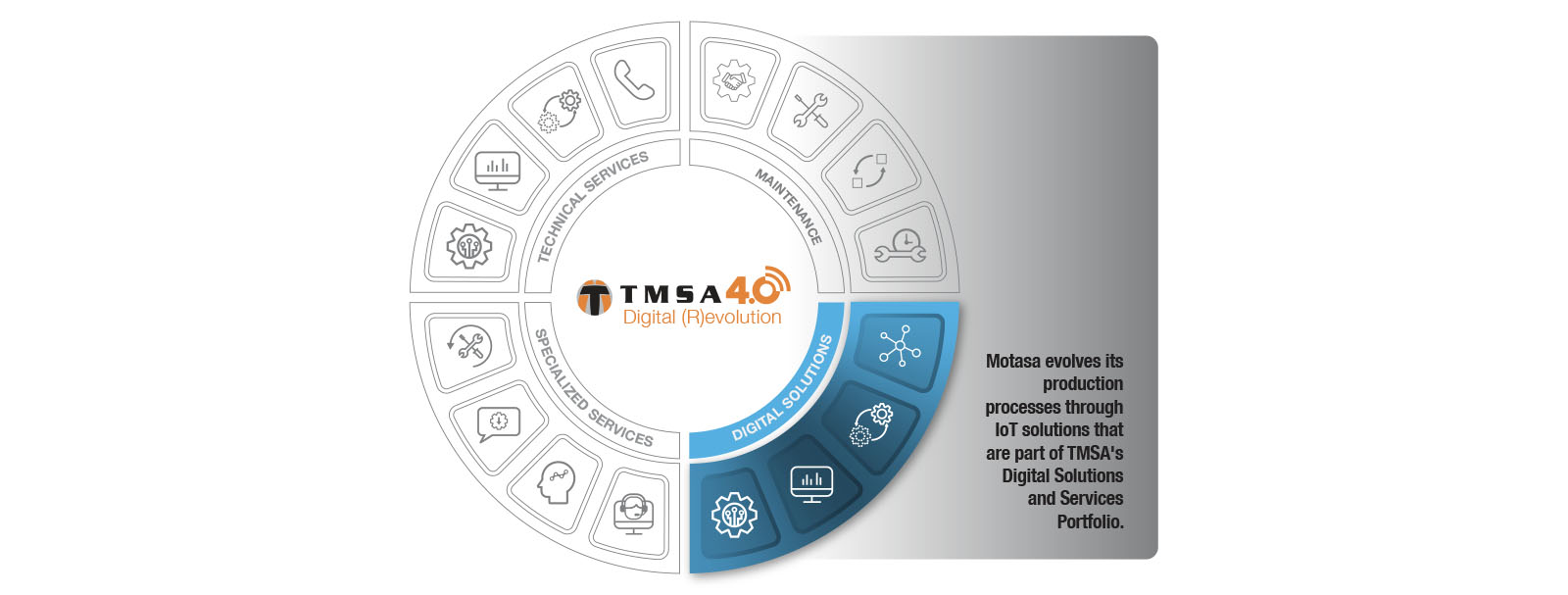

TMSA 4.0 Platform - Digital Revolution brings together a unified portfolio of Digital Services and Solutions that add value to the equipment produced by TMSA operating with the most advanced technology for handling solid bulk.

OBJECTIVES:

- Monitoring of the main components of the equipment, through analysis and data collection.

- Application of the fundamentals of prescriptive maintenance whose decision making is done in an automated, fast and effective way.

INSTALLED SOLUTION:

Through TMSA's loT (Internet of Things) technology implemented in a HE-23 / 900x2000 grain cleaning machine, with a cleaning capacity of 320 ton/h and a 30 hp fan, which stands out for its constant production through the feeder variable flow controlled via frequency inverter, allowing settings for different types of grains. The loT solution provided the monitoring of the main components, through the analysis and data collection with the application of the fundamentals of prescriptive maintenance, whose decision-making is done completely automatically, quickly and effectively. The use of multidata, provided by the monitoring dashboards, facilitated the analysis of the technicians and the production team, since the system provides a significant number of information, improving decision-making in a much more assertive and based way, reducing the time evaluation of the equipment and facilitating a much more effective maintenance plan. Thus, the company will enter a new stage of maintenance, prescriptive maintenance, where the measurement and analysis of data take place in real time, with no need for a technician to travel to the equipment location to collect the data. Moreover, it also has the resource of the database and history, ensuring more assertiveness.

CUSTOMER TESTIMONIALS

“For us it was important to find in the same company the equipment expertise and the needs of our process and also the knowledge to implement the technologies that will put us one step ahead in the journey of Digital Transformation”

Gilberto Aguirre - Industrial Manager of Motasa.