Solution that reduces the water present in iron ore tailings during the filtering process

PROJECT SCOPE

Vale, a Brazilian multinational mining company and one of the largest logistics operators in the country, has increasingly invested in sustainable and safe solutions. Proof of this is that, by 2024, the company should invest around BRL 12 billion in new solutions to reduce the disposal of tailings in dams.

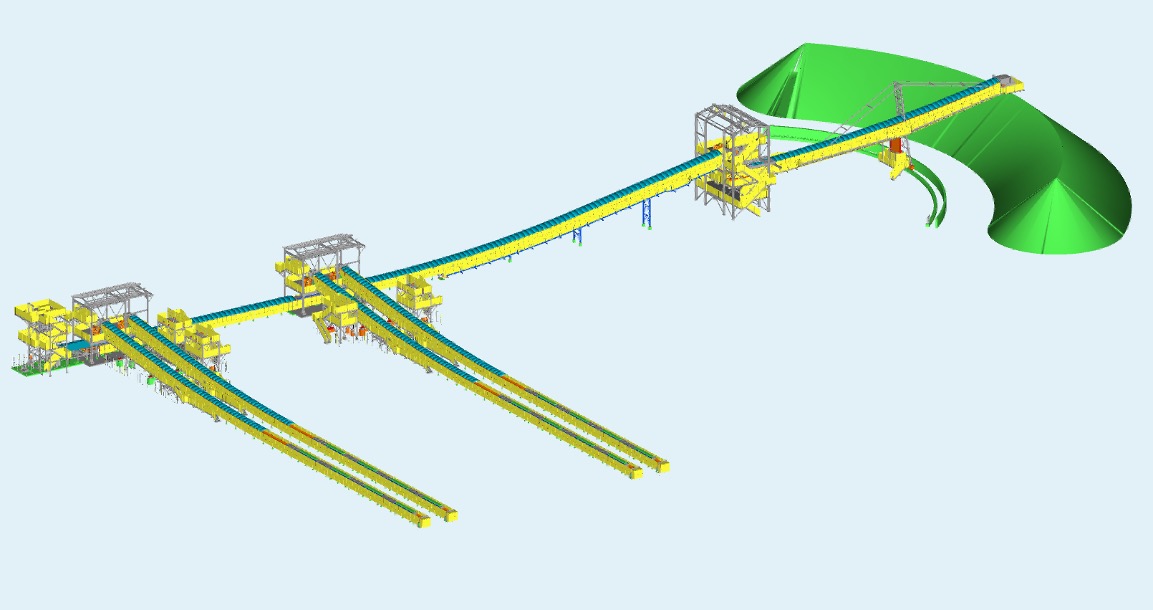

The use of filters in the operational plants makes it possible to segregate the water from the tailings generated in the ore treatment plants. Belt conveyors and radial forklifts developed by TMSA are responsible for moving large volumes of filtered tailings to the piles, where the stable and safe storage of waste occurs, reducing dependence on dams and extending the useful life of some of VALE's mineral assets.

To put the construction of the filtering plants into practice, VALE had the support of TMSA, which was responsible for supplying the conveyor systems used in handling the tailings.

SOLUTION PROVIDED

The project includes equipment for three VALE tailings filtering plants. The first, located in the Vargem Grande complex, is already in operation and has three TMSA belt conveyors and a radial forklift, which together have the capacity to stack up to 1,200 t/h of filtered iron ore tailings.

The equipment was developed to meet strict quality requirements and a challenging deployment schedule. During the project, TMSA bet on the use of the BIM (Building Information Modeling) methodology, which allows the creation of 3D digital models of the equipment, to overcome these challenges.

Several studies were carried out at all stages of the project, which should contribute to reducing the customer's costs in the implementation, maintenance and operation of industrial facilities. The use of virtual models also allowed the early identification of interferences and incompatibilities, mitigating errors, failures and additional costs during the stages of construction and assembly of the conveyor systems.

The second filtering plant, this time in the Itabira complex, with a stacking capacity of 4,800 t/h of filtered tailings. Continuing the project, the construction of a third plant is also planned, with a stacking capacity of 3,400 t/h of filtered tailings. Both will feature TMSA technology, consolidating the company as an important provider of solutions for the mining segment.

ADVANTAGES

• Water recycling can reach 95% of the process water; • Easier to obtain approval from the environmental agency, due to the elimination of dams.

BENEFITS

• Significant reduction in the area for disposing of tailings; • Minimal environmental impact, allowing the elimination of dams.

LEARN MORE:

TAILINGS: residues (sand, clay) that result from the processing of ore and are discarded and placed in dams or piles.

FILTERED TAILINGS: waste that has its moisture (water) removed through a filter in the treatment unit.

STERILE: all material that is removed in a mine along with the ore and is not used economically, being discarded and placed in a pile.

“Our ability to develop complex projects that meet high quality and safety requirements was essential for us to be chosen by VALE as a partner in this endeavor. Together, we built a highly customized solution that integrates different disciplines and meets the mining company's current needs.”

TMSA Engineering Manager, Rodrigo Souza.

3D Digital Models - Cost reduction in the implementation, maintenance and operation of customer facilities

3D Digital Models - Cost reduction in the implementation, maintenance and operation of customer facilities

Download this documento in PDF: